Traceability

Analysis

Predictive maintenance

Where you loose time

Most small and mid-sized companies loose a lot of time while growing due to to little overview of all processes taking place parallel in production. Often times costs for production management Systems are very high and the systems are to complex for long-term employees.

We offer a cheap, efficient and easy to use application especially created for the needs of small and mid-sized companies. Our goal is to give you a perfect overview and transparency of your production. E.g. heath level and cycle rate of your machines, performance of your employees, next tasks.

With our solutions you will save not only time.

Time Saving due to better overview

Cost Matching

Error Analysis

d-dispensing

Our easy to use, fast and cheap option to get your Mettler Toledo Scales connected to your ERP-System. d-dispensing loads automatically all necessary data from your existing database and communicates back all data. Get a perfect tracability for all your products, components and batches within one click.

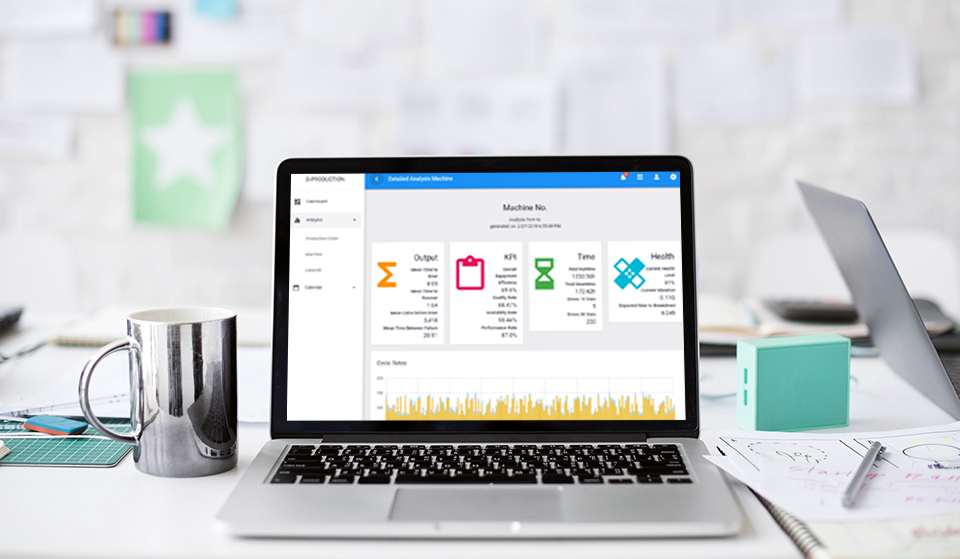

d-production

A industry leading solution for a overview of all your machines and lines as well your employees. Get your production manager and the controlling detailed information easyly without the need of paper or addtional hours on PCs.

dd-management

Digital Management for processes, documents and training. Publish all documents and processes company-wide and ensure sustainable quality management across all locations

Introducing new services and customer-tailored solutions

Industry techniques develop and so do we. During recent years, we introduced new software for dispensing, production overview, live calculation (during running production) and many others.

What People Say

We are using d-dispensing for about 3 years and are very pleased with its performance. It is seamlessly integrated with our ERP-System. It provides not only hazard symbols but also from ECHA, Toxnet and COSING. It totally changed the way we work to the better.

Customer, south of Germany

d-production gave me the ability to manage 8 Lines in three plants and to know immediatly when a line has problems. Furthermore with the live calculation feature I can keep an eye on the costs very easily.

Customer

Our unplanned downtimes had been reduced by nearly 90% due to predictive maintenance in d-production. The health-Level in % as well as the calendar with the expected fault-days of my machines helped us a lot to have a very good overview and great maintenance of all equipment monitored.